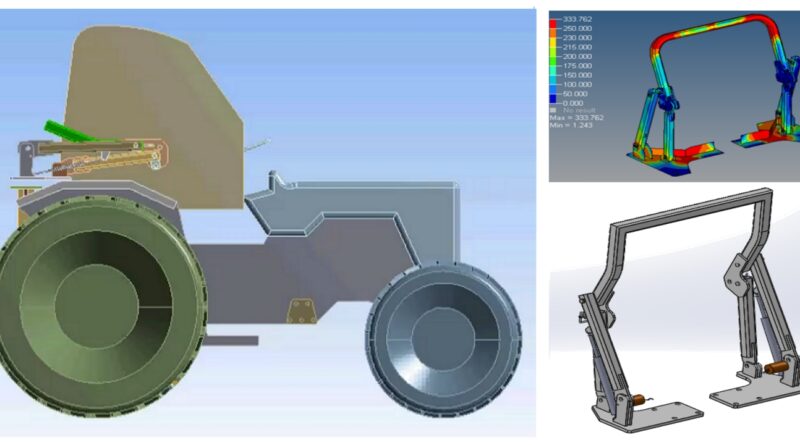

THE DRIVER SAFETY IN CASE OF TRACTOR OVERTURNING: THE “AUTOROPS”

|

TESTO Specialized crops in Italy are widely diffused in hilly areas, often with remarkable slope. They represent obviously critical safety conditions for agricultural mechanization. The main safety measure adopted to protect the operator in the event of the tractor overturning has been the fitting of a protective steel structure around the driver’s place (the ROPS, Roll Over Protective Structure), able to protect the driver in the event of overturning, of course with his/her seat belt regularly fastened. One of the ROPS types allowed by the main international Standards for the fitting on tractors used in vineyards and orchards consists of a simple two-post roll bar located in front of the driver’s seat, which can be lowered by approximately 90 °, rotating it on pins and placing it in a horizontal position, i.e. that of resting. This is also to allow the travelling of narrow track tractors in the inter-rows of specialized crops, without risking damaging the lower branches of the canopy and allowing recovering in buildings with low openings. Currently, the management of the roll-bar is manual: this task, theoretically to be repeated several times in a single day, is in fact ignored by almost all the operators, who therefore actually work with the roll-bar always lowered, i.e. without any overturning protection. In this regard, unofficial statistics estimate 15-20 fatal accidents per year due to overturning involving narrow track tractors, effectively equipped with rollbars, but having the ROPS in rest position at the moment of the event. A rather promising opportunity seems to be the automatic folding-down of the roll-bar (therefore the preparation of an AUTO-ROPS), that could be managed both by hands thanks to the operator’s intervention or, as an alternative, controlled autonomously in regard of the occurrence of given technical-operating conditions. The “AUTOROPS” project is aimed at developing different specimen of rollbar at different levels of automation, i.e. with increasing movement autonomy. The different solutions identified can be applied, as appropriate, to both new tractors, and above all for updating the tractors already working, which for various reasons do not have a ROPS, or it does not comply with the requirements of the dedicated regulations. more info CONTACTS Domenico Pessina domenico.pessina@unimi.it |